- Employ visual aids like infographics to depict the scope and targets - Use storytelling methods to generate the aims relatable and engaging

Process validation will be the Evaluation of knowledge collected through the entire design and manufacturing of a product so as to affirm the process can reliably output products and solutions of a established common. Regulatory authorities like EMA and FDA have released guidelines associated with process validation.[1] The purpose of process validation is to make sure diverse inputs bring on reliable and good quality outputs.

The next phase includes demonstrating that the process is able to continually producing products that satisfy the predetermined top quality characteristics. It incorporates the execution of validation protocols to confirm the process general performance and the gathering of information to help the validation.

It should also handle the validation of important process parameters plus the validation of analytical methods utilized to evaluate solution high-quality.

Process validation takes advantage of aim proof to establish that the process is repeatable and, importantly, to determine the way it is repeatable. The process allows test variability to make certain diversified inputs will proceed to produce reliable merchandise good quality.

Validation Summary Reports deliver an outline of the entire validation job. Once the summary report is signed, the validation task is considered process validation in pharmaceutical industry to be comprehensive. When regulatory auditors critique validation jobs, they usually begin by reviewing the summary report.

PQ is the ultimate step from the process qualification phase and includes verifying that the process continually generates goods conforming to their predetermined specs.

PQ is the final phase from the process qualification stage and consists of verifying the process regularly generates products conforming for their predetermined specifications.

In conclusion, process validation is a crucial component of excellent assurance within the production get more info industry. It ensures that producing processes are effective at continually developing superior-top quality products which fulfill shopper specifications and regulatory requirements.

Use process validation report templates on mobile units like smartphones, tablets, and iPads—even even though offline.

Aseptic process simulation (APS) is essential for validation of an aseptic manufacturing process and…

In the course of the process design and style phase, it is actually crucial to make certain that all areas of the process are extensively recognized and documented. This consists of not just the complex specs but additionally the likely affect of varied components around the process effectiveness.

Any deviations or traits that might perhaps impression solution good quality have to be recognized and addressed instantly.

The 3 phases of process validation are process style, process qualification, and ongoing process verification:

Ashley Johnson Then & Now!

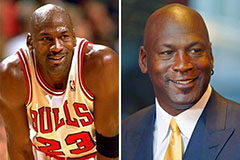

Ashley Johnson Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now!